VOGEN’S production possibilities

- qualified production and technology staff,

- own production halls with administrative and social buildings,

- machine park, including: CNC plasma cutting machine and mechanized beam welding line,

- modern welding equipment,

- own transport.

The company has its own technological facilities with qualified and experienced engineering and technical staff, as well as a well-prepared quality control team with international qualifications.

Many years of experience of our production personnel and factory equipment allow us to use a wide range of available welding methods:

121 – automatic submerged arc welding,

135 – arc welding (MAG) in an shield of active gas with consumable electrode,

136 – arc welding (MAG) in an shield of active gas with flux-cored, consumable electrode,

138 – arc welding (MAG) in an shield of active gas with a metal cored, consumable electrode.

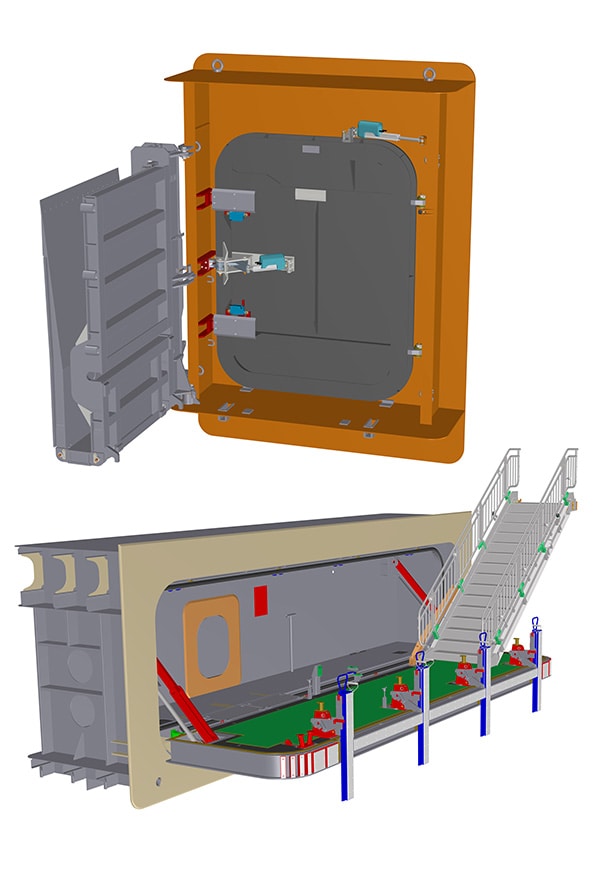

Our products are equipped with dedicated electrical and hydraulic systems and they are tested before dispatch to the customer.

All processes, on preparing stage and during production itself, are executed in line with:

- Management System, in accordance with ISO 9001:2015, certified by BSI Group;

- Company’s Production Control, in accordance with PN-EN 1090, PN-EN ISO 3834-2, certified by Office of Technical Inspection in Poland (UDT);

- Dedicated software system -ERP 2, MES;

- International Classification Society for ships like DNV, LRS, ABS, RINA or BV.

Above mentioned resources allow us to comprehensively produce steel constructions up to 700 tons.